How can Trackgent

apply to various industries?

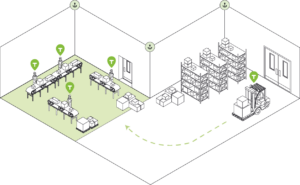

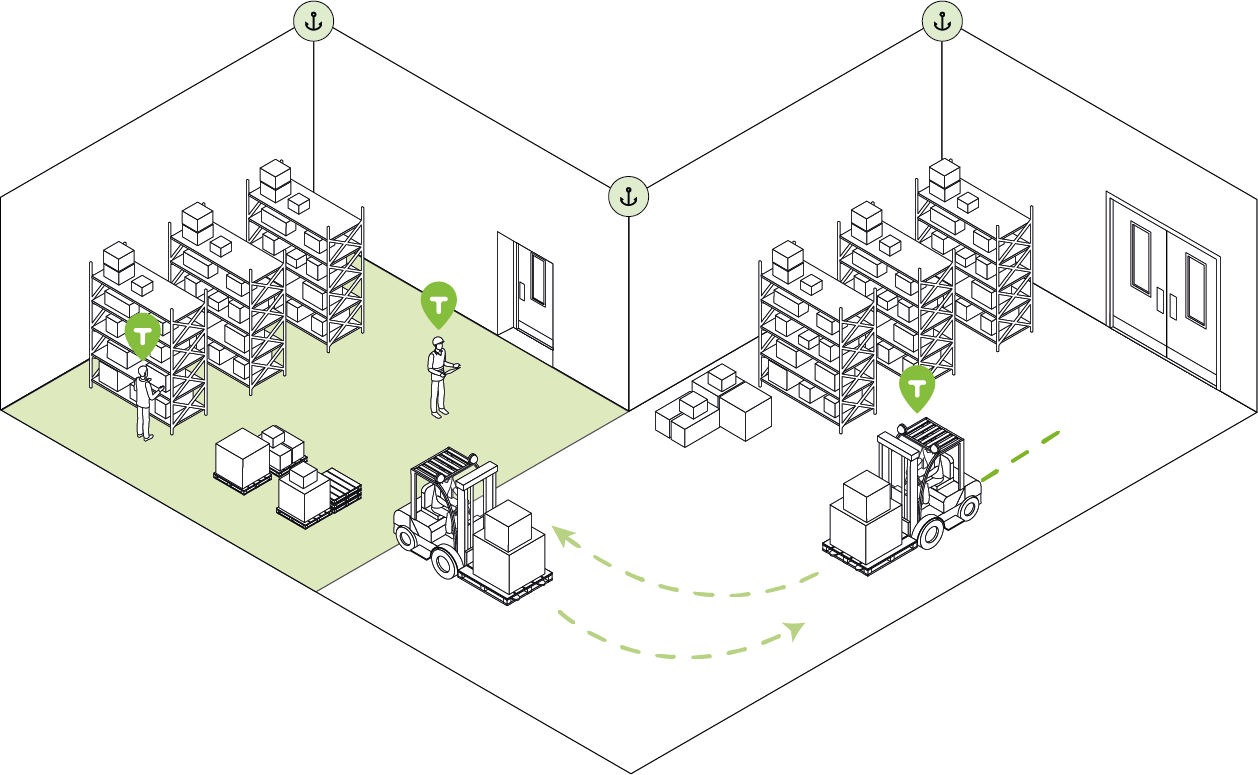

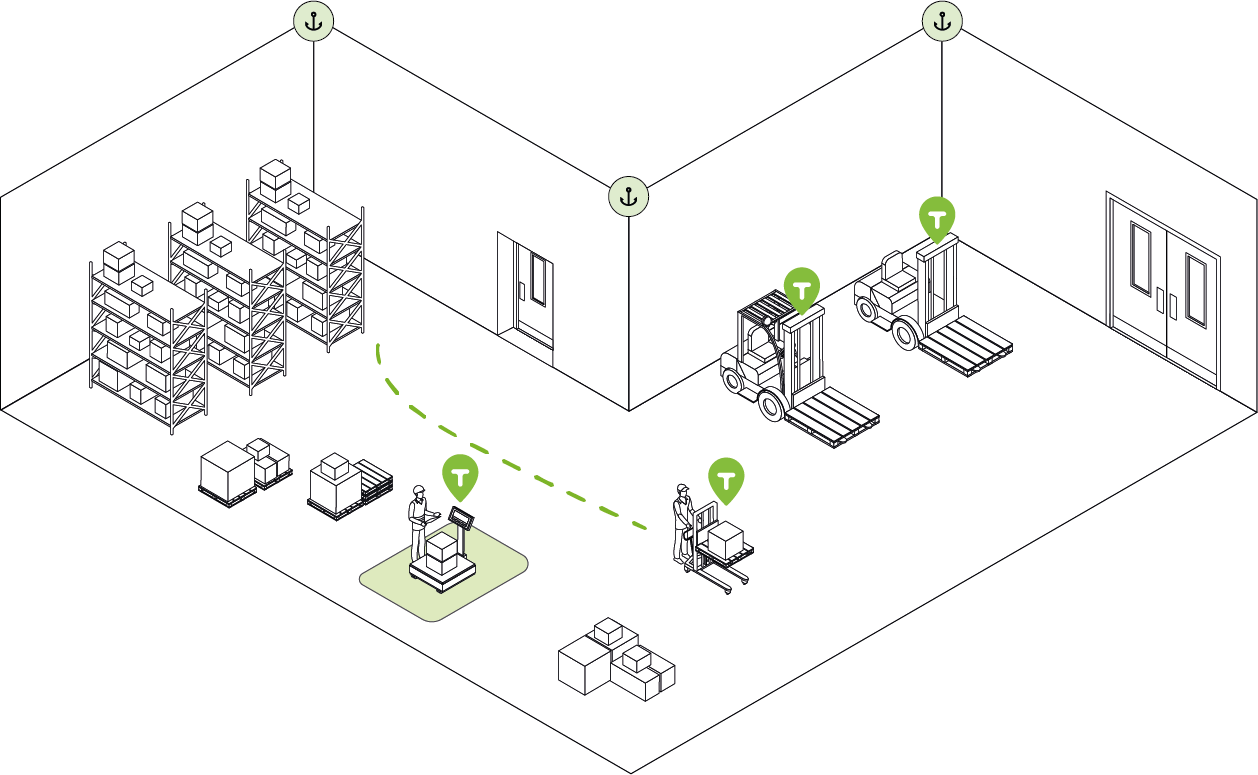

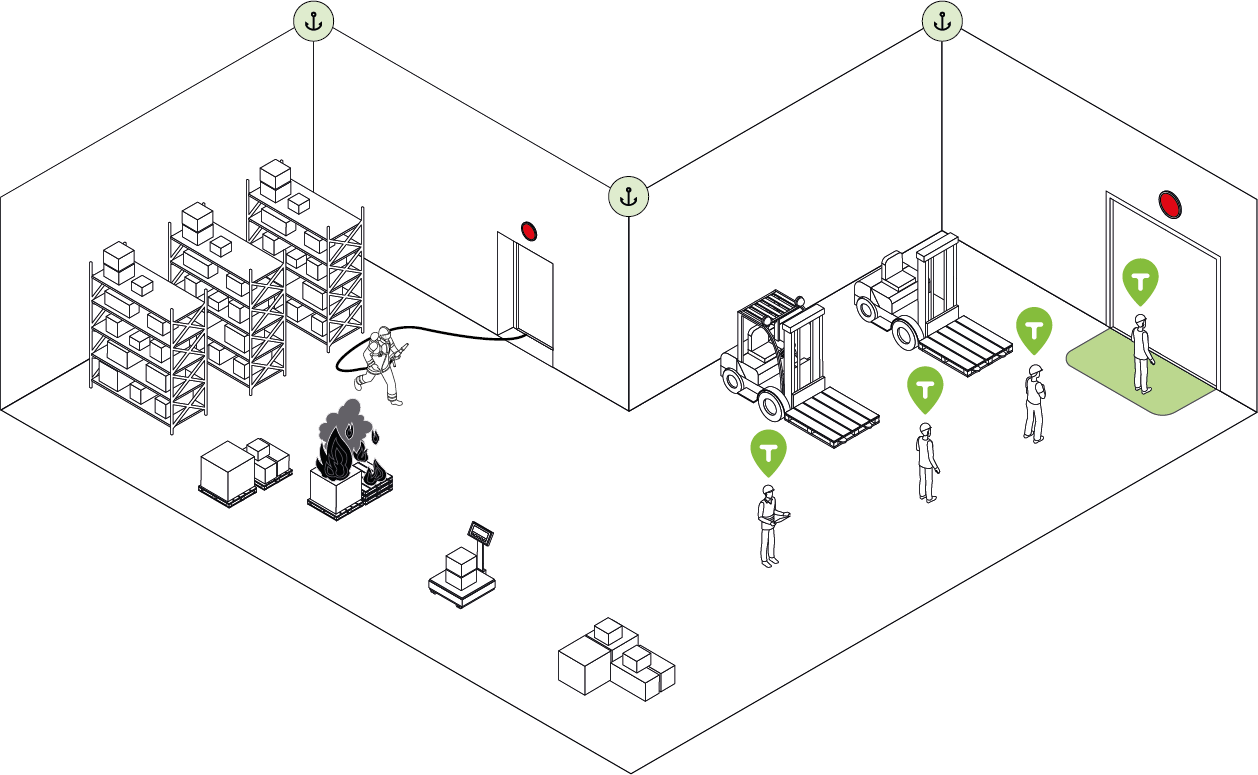

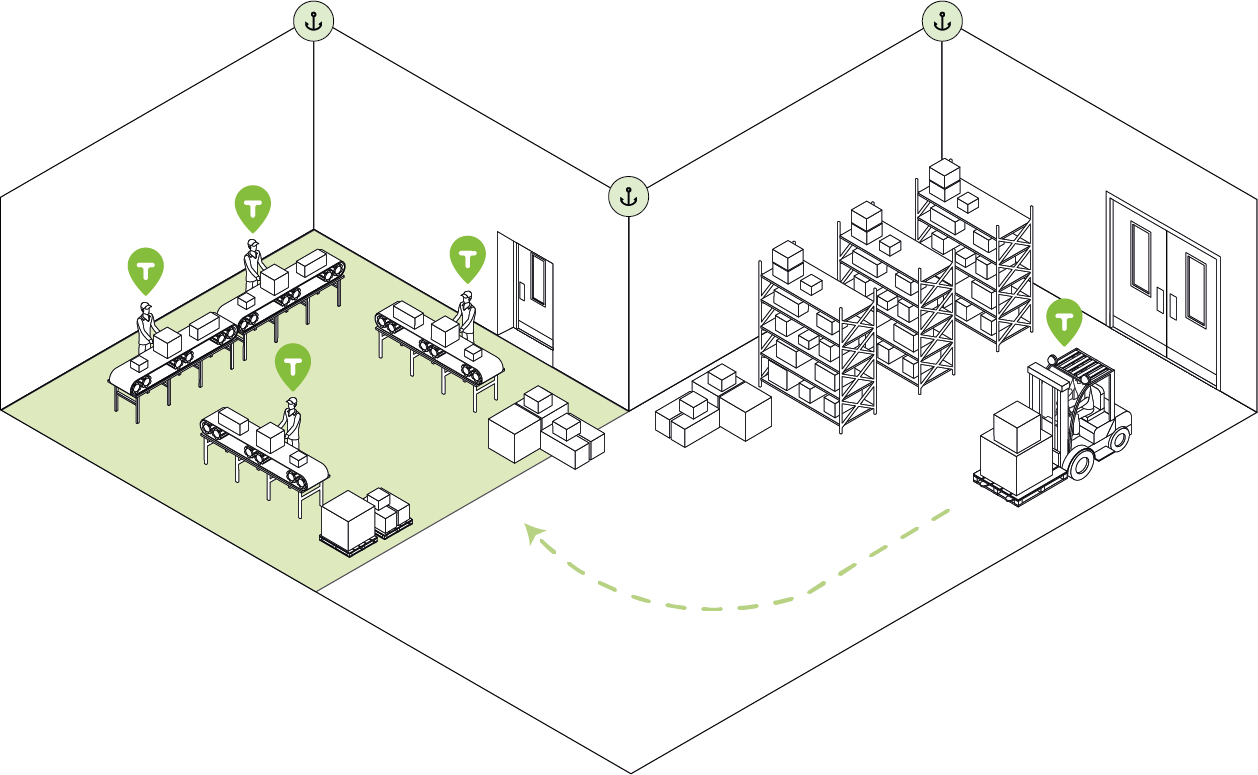

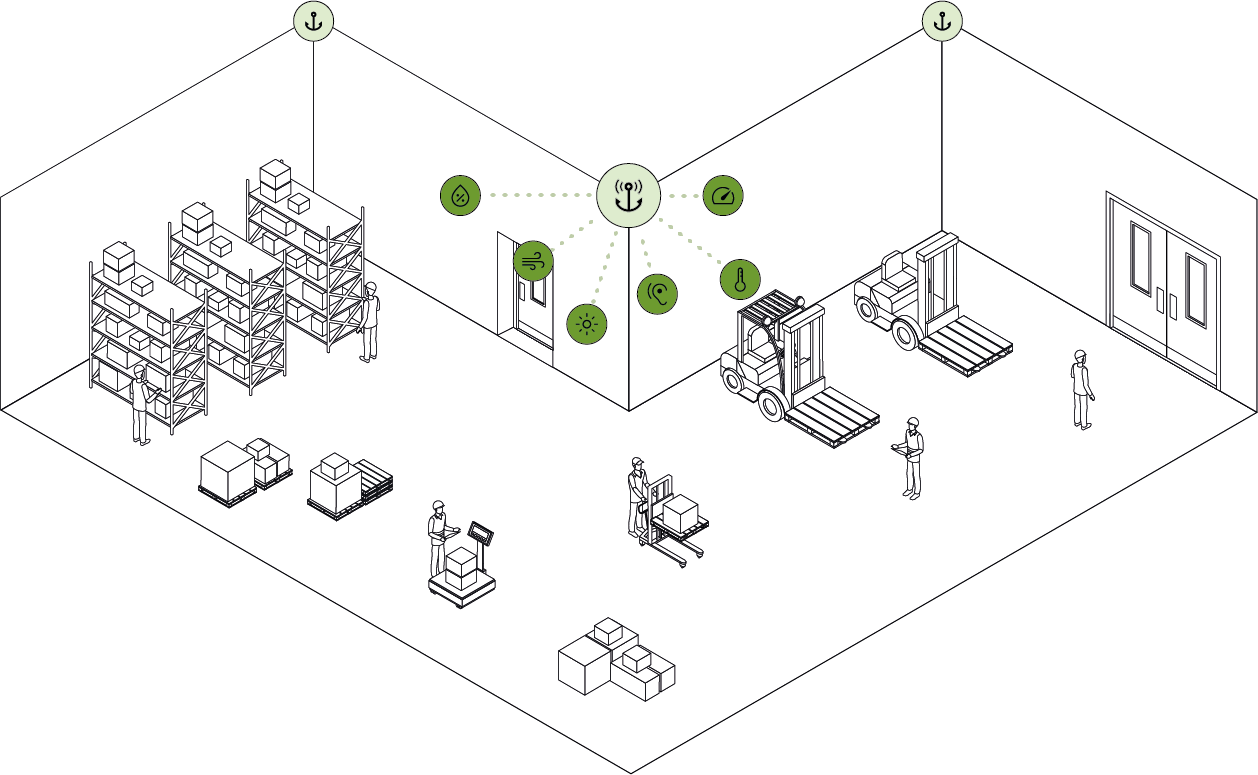

Different industries face different challenges in the area of improving workflow efficiency and safety. An RTLS solution can be helpful in various scenarios enabling workflow management based on monitoring the position of workers and devices within different industrial sites.

- Prevent accidents by monitoring forklifts and people and implementing rules for potential collision detection.

- Measure speed of the forklifts against set parameters.

- Stop dangerous equipment when a worker is in an endangered position.

- Allow only qualified workers to power on given device.

- Support evacuation processes by knowing the current or last known position of an object.

- Automatically count tags in evacuation zones.

- Optimize processes in your factory using Lean Management techniques correlated with additional data.

- Eliminate the risk of downtime by speeding up a location of a maintenance team members operating on the site.

- Integrate Trackgen with other IoT devices to gain additional knowledge on specific environmental factors in your factory.

- Trackgent can be integrated as a support tool to any ERP/CMMS software – no need to be vendor-dependent!

Well-though solution

for various industries

Learn about Trackgent benefits

Installation and maintenance without interference in the facility’s infrastructure.

No impact on the proper operation of other industrial devices on site.

Real-time alerting and historical data monitoring (generated heat-maps).

Possibility to equip the system with RFID or NFC tags, allowing integration with access or time-keeping systems.

Ability to customize the tag according to workplace needs, e.g. in the helmet, protective clothing, shoe.

Positioning with an accuracy of 20 cm.

Learn about our industry implementations

Discover in which industries Trackgent was already found efficient and helped optimize workflows

Would you like to check how the solution works live?

Let’s set up a demo session directly at your facility.